In the evolving landscape of industrial automation and mechanical engineering, pneumatic cylinder technology continues to play a key role in driving precision, power, and efficiency. Modern pneumatic cylinders are designed to deliver smooth and reliable motion control, helping industries achieve optimal performance across a wide range of applications. By integrating advanced pneumatic cylinder systems, businesses can significantly enhance machinery performance while maintaining cost-effectiveness and sustainability.

Understanding Pneumatic Cylinder Technology

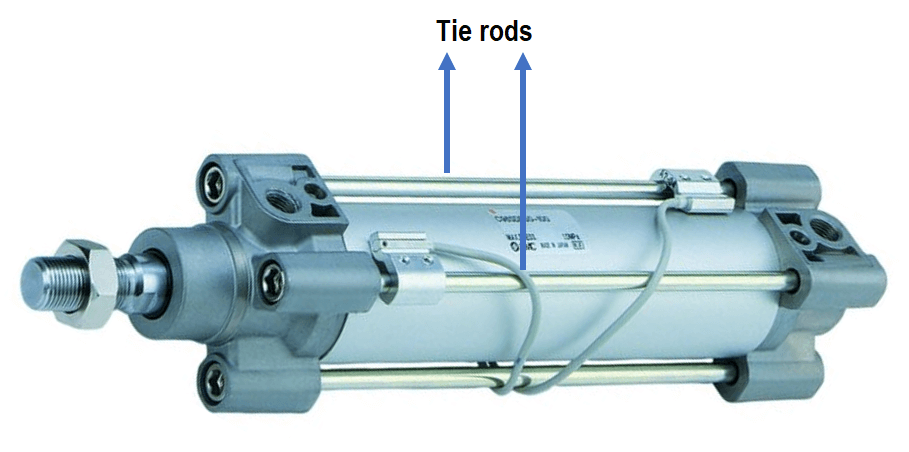

A pneumatic cylinder is a mechanical device that uses compressed air to produce linear or rotary motion. It converts the energy of compressed air into mechanical force, enabling controlled and efficient movement in machinery and automation systems.

Main components include:

- Cylinder barrel: Holds compressed air and allows piston movement.

- Piston and rod: Convert air pressure into mechanical motion.

- Seals and bearings: Ensure airtight operation and reduce friction.

- Ports and valves: Control air flow and direction.

Benefits of Using Modern Pneumatic Cylinders

Modern pneumatic symbols are designed with improved materials, precision engineering, and innovative sealing systems that enhance durability and operational efficiency. They are reliable, cost-effective, and suitable for high-speed automation tasks.

Key benefits include:

- Increased efficiency: Delivers fast and accurate motion with minimal energy loss.

- Durability and longevity: Built to withstand continuous operation and harsh conditions.

- Low maintenance needs: Simple design allows for easy inspection and servicing.

- Cost-effectiveness: Offers high performance with lower operating costs.

- Environmental friendliness: Utilizes clean, compressed air for operation.

Applications Across Diverse Industries

Pneumatic cylinders are essential in industries that rely on consistent and precise mechanical movement. Their versatility allows them to be integrated into numerous systems, from manufacturing to packaging and beyond.

Common applications include:

- Operating robotic arms and assembly line equipment.

- Controlling conveyor systems and automated sorting machinery.

- Powering clamping, lifting, and pressing tools.

- Assisting in motion control for automotive and packaging equipment.

Innovations Shaping Modern Pneumatic Systems

Recent advancements in pneumatic cylinder technology have resulted in cylinders that are more compact, efficient, and intelligent. These innovations improve performance while supporting automation and sustainability goals.

Emerging trends include:

- Smart sensors integration: Enables real-time monitoring and precision control.

- Lightweight materials: Reduces energy consumption and enhances mobility.

- Compact designs: Increases flexibility in limited-space installations.

- Energy-saving systems: Optimizes air usage for sustainable operations.

Driving Performance and Reliability Forward

Enhancing machinery performance with modern pneumatic cylinder technology is a smart investment in productivity and long-term reliability. These systems provide the speed, strength, and precision needed for advanced automation and industrial efficiency.

By embracing innovative pneumatic solutions, organizations can ensure smoother operations, reduced downtime, and improved energy efficiency. As industries continue to evolve, pneumatic cylinder technology remains a cornerstone of motion control and mechanical excellence.